Whitepapers > Whitepapers1

IMPLEMENTATION OF UNCAL ESB IN THE LOGISTICS SYSTEM

Introduction

Nowadays, we must be familiar with the word logistic. In the Oxford Dictionary, Logistics is the process of planning and organizing to make sure that resources are in the places where they are needed so that an activity or process happens effectively. When talking about Logistics in the company, it is very closely related to planning and controlling the flow of goods and materials. The objective of logistics is to help goods or materials arrive at their destination in the right condition, quantity, and time. The company must carry out a series of activities such as the procurement process; production activities (manufacturing support), and physical distribution.

In its implementation, logistics activities have performance standards that must be achieved. The level of performance that logistics activities want to achieve is a balance between the quality of service expected by customers and all costs incurred to achieve company goals. To improve logistics performance there are two main factors:

- Service factor, the level of company service to customers.

- Cost factor, the cost spent by the company to handle service to consumers.

Several elements play an important role in logistics. Such as optimal human resources, safe and secure handling of goods, continuous handling, and capable technology. Logistics has become even more important throughout the years. Suppliers, manufacturers, and distributors have had to improve their logistics processes to meet the demand for quicker, more convenient delivery of a wider variety of goods. They also have had to better integrate and digitize their processes and systems to improve supply chain visibility. By becoming more modern with digitization, all aspects of your production and logistics are intelligently linked together, allowing for optimized big data management, and will make every logistical activity much easier. With all of the above, it will create the right logistical activities.

Why integrate?

Companies that integrate their purchasing and logistics functions deliver better business results.

The value chain in the digitization of the petrochemical industry

Reserves for improving the efficiency of petrochemical production based on “Industry 4.0” (A. I. Shinkevich 2019).

The connected process: In-depth substantive examination, optimization, and analytics through digital doubles (twins).

The connected assets: Broad ecosystem of expertise and capabilities, predictive control, increased operating time, reduced downtime.

The connected staff: Improving the quality of solutions through data analysis, safety, and employee satisfaction.

The connected enterprise: Unique industrial solution, integrated solutions for the entire enterprise.

Implementation of UNCAL ESB in Logistics

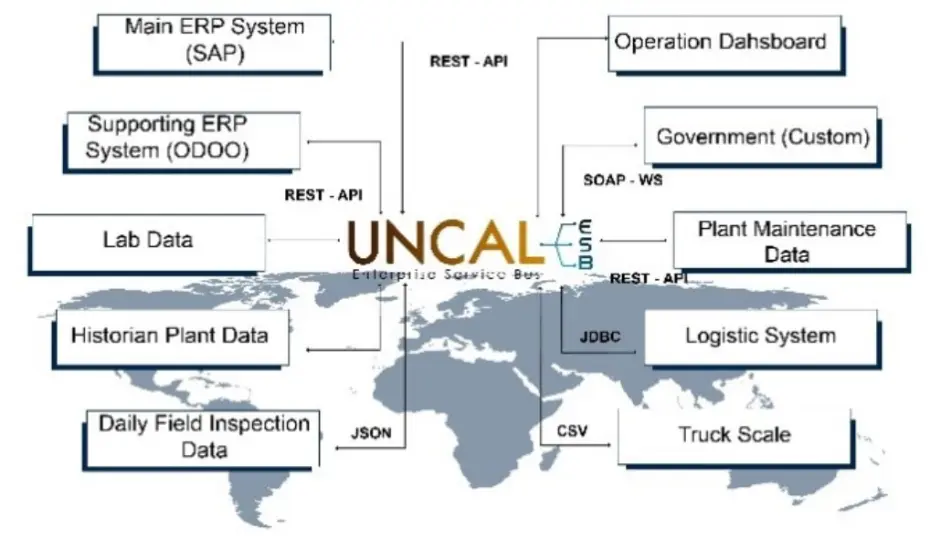

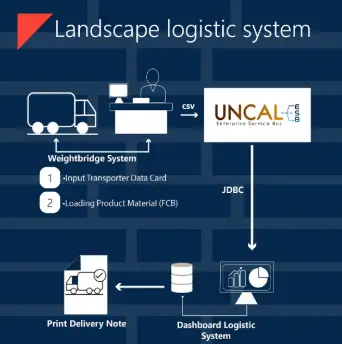

Right now, everything is all about digital. With rapid changes in every sector of industry especially in technology, sector industries should start to do a digital transformation. An example is from the manufacturing industry (PT MCCI) which plans to implement Digital Transformation in business processes and logistic systems. Digitalization will be integrated solutions for the entire enterprise. Every data exchange process between stand-alone systems which is usually done manually, will be integrated automatically so that the exchange of data and information becomes faster, paperless, automated, real-time, more accurate, and supervised. It all can be done with UNCAL ESB. UNCAL ESB functions as an integrator to connect information from various existing systems.

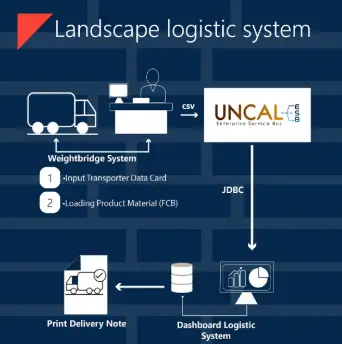

From various systems, the technical implementation of UNCAL ESB in each system has different methods to communicate and can be managed using one platform only and can monitor to see how data transfer is going from one to another. PT MCCI wants to integrate every business process in their corporate, to connect every asset, and connect staff/employees to get employee satisfaction. One of the logistic processes that will be developed is the integration of Weighbridge into the Web Portal which will be able to generate the Surat Jalan (Delivery Orders) and Tempat Penimbunan Sementara (TPS) Online. In this case, the objectives of Digital Transformation in Logistic Systems are:

- to avoid repetitive similar data input that possibly makes inconsistency data information.

- to accelerate the process of making the Delivery Note.

- to minimize errors in making Delivery Note documents and reports.

- stored in a database (traceable).

Surat Jalan (Delivery Orders)

To create delivery orders, in the existing system, the manual data input is performed repetitively by different officers for different purposes. This can result in inconsistent data due to human error factors. By integrating Weighbridge into the Logistic System Web Portal, input data will be one time performed for multiple purposes and will eliminate inconsistent data due to human error. There are two types of delivery order process:

1. Workflow of process Bulk

Here is the workflow of process bulk to generate delivery orders:

- The transporter enters the Weighbridge to register the Card.

- Transporter enters scaling Tare Weight.

- Weighbridge Officer inputs the transporter data card to the system. Input data is performed by the System and continues to the loading process.

- The transporter moves to the Cylo to perform the bulk loading process until finished.

- The transporter moves to the Weighbridge for scaling gross weight and the driver takes the Measuring Notes leaves the Weighbridge and goes to Logistics.

- Logistics create delivery orders and the system will automatically send email notifications of COA requests to QA (Quality Assurance) and then print COA.

- Driver takes delivery order and COA from Logistics.

2. Workflow of process FCB

Here is the workflow of process bulk to generate delivery orders:

- The transporter enters the Weighbridge to register the Card.

- Weighbridge Officer inputs the transporter data card to the system. Input data is performed by the system, continuing to the loading process.

- The transporter moves to the warehouse to perform the FCB loading process until finished.

- The transporter moved to Logistics to request delivery orders (Surat Jalan) and COA.

- Logistics create delivery orders (Surat Jalan) and the system will automatically send an email notification of the COA request to QA (Quality Assurance), then Logistic print COA.

- The driver takes delivery orders (Surat Jalan) and COA from Logistics.

Tempat Penimbunan Sementara (TPS) Online

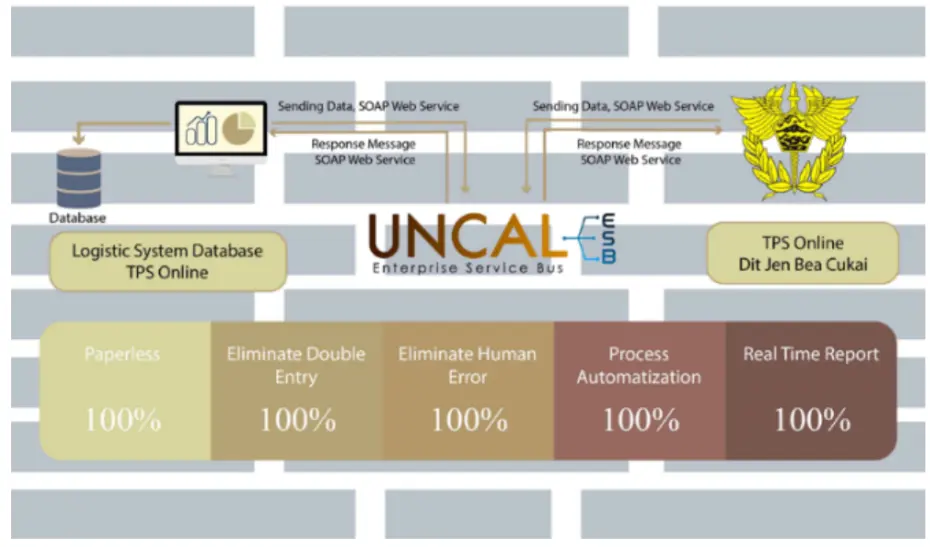

PT MCCI has a large storage tank which can be called Tempat Penimbunan Sementara (TPS), According to the regulations, data must be reported to TPS Online. UNCAL ESB can help how data from Field Teams can be sent directly in real-time. If previously still using the manual method, by writing on a paper, then inputting to Excel, next import to online systems, nevertheless with UNCAL ESB, PT MCCI can build systems and integrate with Bea Cukai’s Web Service. UNCAL ESB can directly send data with the result that the needs to be achieved can be fulfilled in this business process.

Here is the workflow of TPS (Tempat Penimbunan Sementara) Online:

- Logistics send forms (various forms) to WEB SERVICE Custom via UNCAL ESB Then the web service responds for being taken by UNCAL ESB Send to logistic.

- Logistics request form data to WEB SERVICE Custom via UNCAL ESB Web service receives and sends the response in the form data that has been saved to logistics via UNCAL ESB.